-

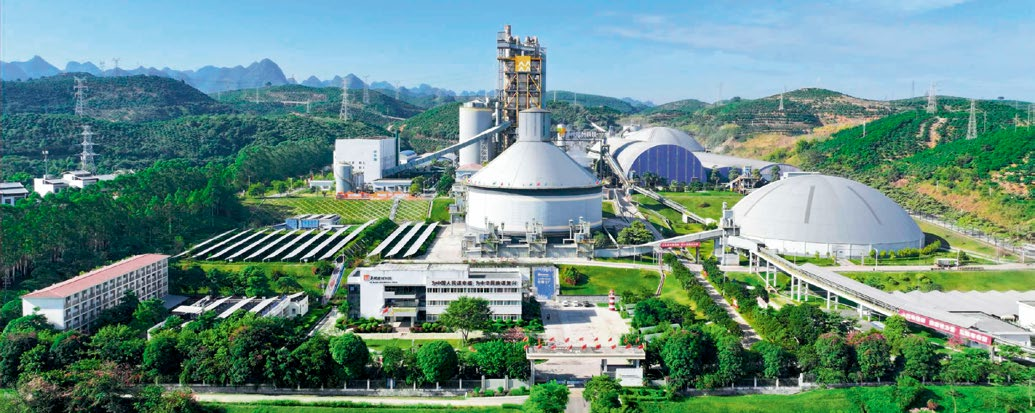

>CR Building Materials Tech’s Tianyang Industrial Park Tianyang District in Baise City, located in the western part of Guangxi Zhuang Autonomous Region and the central area of the You River, is known as the "hometown of Mangoes" and is a home to various ethnic minorities, boasting a beautiful natural environment. However, despite being nestled among green mountains and clear waters, the local government faces the "garbage siege" dilemma during economic development and urban expansion.

Addressing the Dilemma of "Garbage Siege"

"With a population of over 300,000 in the Tianyang District, the government used to allocate 20 to 30 acres of land each year specifically for landfill. As the population grew, the conflict has become increasingly prominent,” said Deputy Mayor of Tianyang District, Ma Song, expressing his concerns. He noted that the garbage disposal process is complex, involving multiple stages such as collection, transportation, treatment, and disposal. Traditional incineration produces air pollution, while sorting waste requires significant investment and high costs for collection and transportation. The lack of adequate waste treatment facilities has resulted in the accumulation of some garbage, increasing subsequent operation and maintenance costs, and causing further pollution to the environment.

CR Cement (Tianyang) Limited, a subsidiary of CR Building Materials Tech, operates a new 4,500-ton/day dry-process cement clinker production line with an annual cement output of 2 million tons, commissioned in December 2010. Huang Liyi, an environmental engineer in the EHS department at Tianyang Cement, joined the company in October 2010 and is primarily responsible for carbon emission management and environmental protection. He shared that in June 2016, Tianyang Cement signed a cooperation agreement with the government in Tianyang District of Baise City to utilize the cement kiln for co-processing urban and rural domestic waste.

"Compared to landfill and incineration, co-processing domestic waste in a cement kiln is a safe and environmentally friendly treatment technology," Huang Liyi explained. Cement production involves "two grindings and one burning”: raw material grinding, clinker calcination, and cement grinding. Urban waste is introduced into the cement kiln during the second stage, participating in high-temperature calcination to produce clinker. Unlike the incineration of domestic waste in power plants, which generates toxic dioxins, the rotary kiln in cement production reaches over 1,450 degrees Celsius, effectively suppressing dioxins without affecting cement quality, thus resolving the "garbage siege" dilemma.

"The entire process is green and pollution-free, representing a 'win-win' model that balances social and economic benefits," Huang Liyi added. For local governments, this project enables the “harmless, resourceful, and reduced” disposal of urban and rural domestic waste, decreasing methane emissions from landfills by approximately 200,000 tons of CO2 annually, thereby supporting local "dual carbon" goals. For cement companies, it reduces the consumption of traditional fossil energy and the damage to the environment and resources.

As of April 2025, Tianyang Cement had disposed of 420,000 tons of local domestic waste to address the "garbage siege" issue in Baise City, saving 12,000 tons of standard coal annually and reducing landfill area by 1,600 acres. Over a decade, this equates to an annual reduction of 14 million cubic meters of methane emissions, bringing strong momentum into Tianyang's "lucid waters and lush mountains”.

Lucid Waters and Lush Mountains are Invaluable Assets

In 2004, Sun Zhen graduated from university and joined CR Building Materials Tech, rising from a technician to General Manager of Tianyang Cement. "The traditional cement industry is typically characterized by 'high energy consumption, high material consumption, high pollution'. It is also a key target for national energy-saving and emission reduction. Energy conservation and carbon reduction are mandatory tasks and inevitable trends for development," he explained.

CR Building Materials Tech actively responds to the national "dual carbon" policy and has been exploring a green, low-carbon development path. Starting from the entire cement production process, the company has proposed the "3C" carbon neutrality theory. "This aligns perfectly with our work!" said Sun Zhen, who uses it as the underlying logic for management, complemented by more detailed measures. The company has gradually explored innovative practices such as co-processing social resources, constructing photovoltaic power generation for “low carbon at the source”, promoting “reduce carbon during the process” through intelligent manufacturing, and achieving “remove carbon at the end” with space biotechnology.

“Co-processing domestic waste in a cement kiln is the first step towards ‘low carbon at the source’,” he explained. The company also installed nearly 10,000 square meters of photovoltaic panels to supply power for production, reducing reliance on traditional fossil fuel electricity. Additionally, a pure low-temperature waste heat power generation system has been constructed, which saves approximately one-third of the company’s purchased electricity, reducing carbon emissions from electricity.

In terms of the "reduce carbon during the process”, the company has made significant investment in equipment upgrades and transformations and energy-saving transformations. Sun Zhen noted that in 2024 alone, the company invested RMB4.61 million in these upgrades. Furthermore, an intelligent information and automation system has been established to optimize production processes, enhance production efficiency, and reduce carbon emissions during production. For example, artificial intelligence is used for automatic deviation correction to ensure the stable remote operation of the entire system, while black screen operations allow the backend to run automatically without manual intervention, significantly reducing energy consumption.

“Remove carbon at the end” explores the full use of renewable resources, such as using arundo donax in space for biocarbon fixation as an alternative fuel, capturing 4.05 tons of carbon per acre.

In addition, the grinding aids for carbon fixation independently developed by CR Building Materials Tech have been used in the cement powder production process, which has also reduced carbon consumption at the end of cement production.

Sun Zhen noted that through these beneficial initiatives, Tianyang Cement has reduced its carbon emissions by 46.07% compared to the beginning of the "14th Five-Year Plan" (2020), truly realizing the goal of "allowing green new productivity to become the driving force for the sustainable development of the enterprise”.

"Lighthouse Factory" Leading Green Intelligent Transformation

On 28 December 2023, the inauguration of the Tianyang Cement’s "Lighthouse Factory" marked it as the first "Lighthouse Factory" in the global building materials industry.

Regarding the application for the "Lighthouse Factory”, Sun Zhen recalled, "During the '13th Five-Year Plan' and '14th Five-Year Plan', CR Building Materials Tech included the intelligent transformation of Tianyang Cement in its strategic planning and initiated a smart manufacturing strategy in 2018, designating Tianyang Cement as a pilot unit to explore full-process intelligent transformation while actively benchmarking and applying for the ‘Lighthouse Factory’ of the World Economic Forum”.

"We focused on enhancing management efficiency through four dimensions: labor efficiency, energy efficiency, sustainability, and replicability, achieving a qualitative leap in organizational restructuring and innovative development,” Sun Zhen expressed his desire to provide replicable management experiences for enterprises in the industry, promoting the cement sector to develop towards green, low-carbon, and intelligent efficiency.

Taking the mine as an example, the limestone mining area is only three kilometers from the factory but is remote with inconvenient transportation. Previously, operations involved complex procedures such as manual blasting and drilling on the site, safety monitoring, slope displacement measurement, loading, and transportation. Now, capitalizing on technologies such as digital mining construction and unmanned mining truck system, automatic transportation route planning and multi-vehicle collaborative operations are achieved, with the “loading, transporting, and unloading” process fully unmanned and autonomous. Sun Zhen calculated that five pure electric unmanned mining trucks reduced operating costs by 83% and annual carbon emissions by 319 tons as compared with nine traditional diesel trucks, effectively supporting energy-saving and carbon-reduction efforts in cement production.

In 2020, the smart manufacturing project at Tianyang Cement had been successively launched, covering production and operation management, 5G private networks, and other digital use cases. It also completed smart construction across the entire process from EHS management, mining, production, quality, equipment, to cement shipping. By 2024, further iterations and upgrades were made around industrial modeling and AI algorithms, based on deep application needs for industrial data and on-site vision.

Over 15 years since commissioning, Tianyang Cement has transformed from a standard traditional cement enterprise into one with multiple application scenarios of artificial intelligence and smart manufacturing. Sun Zheng, who participated in and witnessed this development, feels proud, “We have achieved the goals of ‘safety management, transparent production, stable quality control, connected equipment, and reduced energy consumption’, while completing organizational restructuring and overall optimization and improvement of operational models and personnel quality.”

"Tianyang Cement is a pioneer in the digital transformation of CR and a pilot unit for smart manufacturing at CR Building Materials Tech," stated Xie Ji, CEO of CR. Being recognized globally as a "Lighthouse Factory" is a successful example and milestone that exemplifies CR Building Materials Tech's commitment to green and low-carbon development and its continuous effort for traditional cement manufacturing to transition towards intelligent, green, and high-end upgrades.

"Greening and intelligence are two inseparable aspects of high-quality enterprise development and are also the main directions for the transformation and upgrading of the building materials industry." To this end, Xie Ji envisioned the future, "We will continue to lead innovation in the industry, serve as a ‘pilot-and-demonstration’ model for the green and intelligent development of the industry, actively participate in standard formulation, and contribute to enhancing the green and digital levels of the industry with the strength of CR."

-

Our Philosophy